→ DEFINE – WHAT IS IMPORTANT?

→ MEASURE – HOW ARE WE DOING?

→ ANALYSIS – WHAT IS WRONG?

→ IMPROVE – WHAT NEED TO BE DONE?

→ CONTROL – HOW DO WE GUARANTEE PERFORMANCE?

→ INFORMATION INTEGRITY.

→ MOTIVATION MEASUREMENT.

→ POINT OF USE LOGISTICS.

→ CYCLE TIME MANAGEMENT.

→ PRODUCTION LINEARITY.

→ RESOURCE PLANNING.

→ CUSTOMER CONNECTIVITY.

→ INCREASE PRODUCTION SPEED, IMPROVE QUALITY AND LOWER COST.

→ IMPROVE CUSTOMER PERFORMANCE AND SATISFACTION.

→ OPTIMIZE INVENTORY UTILIZATION – TURNOVER.

→ REDUCE THE HIGH COST OF SCRAP AND REWORK.

→ EXCEED PERSONAL AND COMPANY EXPECTATIONS.

→ CREATE A FUN WORKING ENVIRONMENT.

QUALITY MANAGEMENT

We Follow Total Quality Management Systems Rules

QUALITY OBJECTIVES

-

100% CUSTOMER SATISFACTION SHOULD BE PROVIDED

-

100% ON TIME DELIVERY SHOULD BE PROVIDED

-

0% DEFECT PRODUCTS SHOULD BE PRODUCED

-

0% CUSTOMER COMPLAINTS SHOULD BE ACHIVED

-

5S SYSTEM SHOULD BE FOLLOWED

-

LEAN MANUFACTURING SYSTEM SHOULD BE FOLLOWED

-

AN ISO 9001 CERTIFIED COMPANY

-

SIX SIGMA SYSTEM WILL BE FOLLOWED

-

CONTINUOUS IMPROVEMENT OF ALL PROCESS AND SYSTEM WILL BE ADOPTED

-

25% TURNOVER SHOULD BE INCREASED PER ANNUM

-

25% PRODUCTION CAPACITY SHOULD BE INCREASED PER ANNUM

First We Base on Eight Principles of ISO Certification

- ● We focus on our customers, We understand their needs, We meet their requirements and expectations.

- ● We already provided a good leadership to our organization, our leader takes necessary action to make unity of our organization. He also created an environment the encourages our manpower to achieve our objectives.

- ● We involve our all manpower at all levels. We help our manpower to develop and use their abilities

- ● We use a process approach, so our organization is more efficient and effective

- ● We use a system approach, so our organization is more efficient and effective

- ● We encourage continual improvement, we make a permanent commitment to continually improve our overall performance

- ● We get fact before we decide. We base decision on the analysis of factual information and data

- ● We work with our supplier as a business partner, because we depend on our supplier to help us create value. So we maintain a mutually beneficial relationship with our suppliers.

QUALITY MANAGEMENT

We have been able to maintain our credentials through our uncompromising approach towards quality and thus, have also earned TUV India certificate for following the stringent quality control norms and international standards. The entire production process takes place under the supervision of highly experienced quality control inspectors to eradicate marginal possibility of quality degradation. We manufacture these products as per the exact requirement of the customer whilst maintaining high quality standards. With our consistent efforts, we have surpassed our competitors in the market.

-

Quality Planning

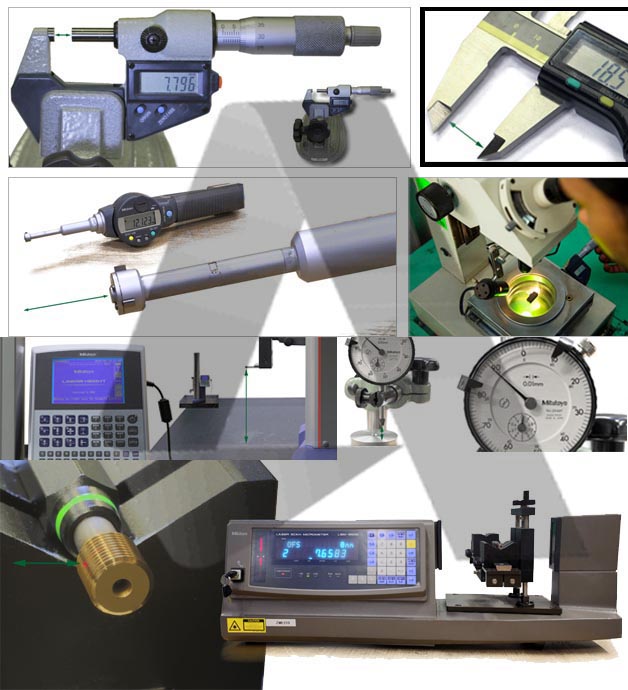

Test Equipment

Trainings

In-Process & Inter-Process Inspections

Equipment Calibration & Maintenance

Up-to-date records of quality standards

Dedicated Engineering Department

Design & Development as per Custom Specification

Vendors Controls & Audits

Statistical Measuring techniques like Variance analysis, SPC, X-Chart, R-Chart, trends.

100% Visual Inspection to ensure 100% visual defect free products.

Yearly Management Audits by TUV Sud

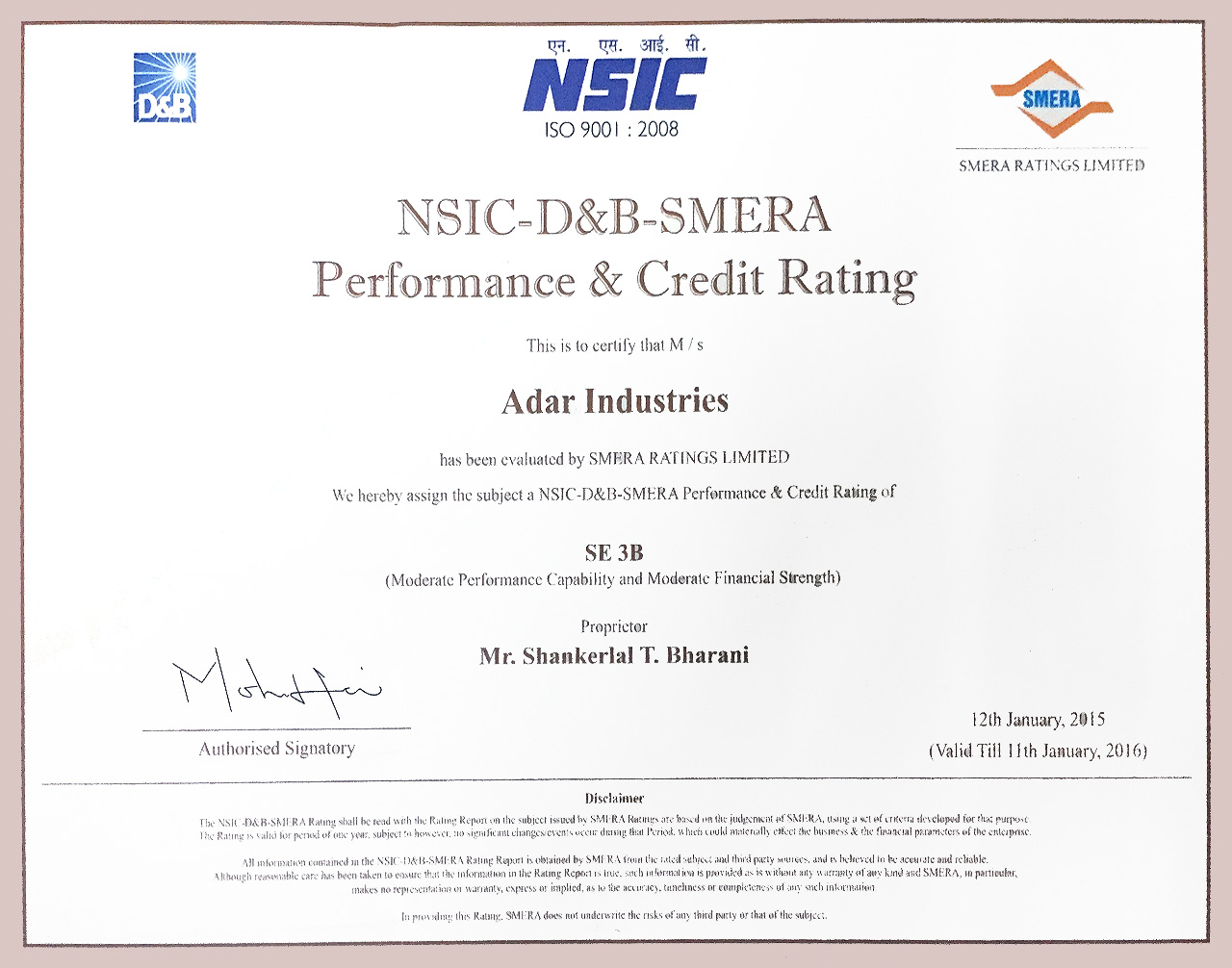

Quality Certificat

To achieve the maximum standard and quality, our quality control team continuously monitors the product and user requirement right from the production stage up to the final dispatch. Due to strict quality control procedures our customers are ensured that their requirements are met accurately and consistency. We are always at services of our valued customers to their satisfaction at the most economical and lowest possible rates.

Certificate of Registration

Certificate of Registration

NSIC Certificate

| TYPE | QUANTITY |

| Profile Projector [PP] 50X | 1 No. |

| Plating Thickness Testing Machine | 1 No. |

| Force Testing Machine | 1 No. |

| Jet Air Pressure Testing Macine for testing ingress Protection (IP) | 1 No. |

| Metal Hardness Testing Machine | 1 No. |

| Centrifugal Deburring-Polishing Machine | 1 No. |

| Vibro Finishing Machine | 1 No. |

| Digital Vernier Calliper [Mitutoyo Brand] | 25 Nos. |

| Micro Meter [Mitutoyo Brand] | 20 Nos. |

| Dial Vernier Caliper [Mitutoyo Brand] | 15 Nos. |

| Torque Testing Machine | 1 No. |

| Ring & Plug Gauges [HIP Brand] for various Threads | 250 Nos. |

| WCP Gauges - Master Calibration | 3 Nos. |

| Pin Gauges-Specific | 550 Nos. |

| Special Structural Gauges to Control Critical Dimensions | 25 Nos. |

| Special Radius Gauges to check radius over components | 20 Sets. |

| We develope special gauges for checking purpose of extra spacification components | |